© 2023 Dr Margaret Sheppard

Building, Brick Making and Construction

Traditionally houses were made of clay bricks and roofed with coconut thatch, supported on wooden coconut beams or for larger buildings they were roofed with clay tiles. The floors were of beaten earth. Materials for these types of building were readily available as were the skills to make them and construct the houses. There are still several of these types of buildings especially in rural areas and they are still being built utilizing these locally sourced materials.

The bricks were made of clay dug out in areas where there was a plentiful supply. Nowadays several families make bricks on a small scale to supply the local market. These houses were typically one storey and largely built without foundations.

Cement bricks are now common. Again these are locally made although there are also factories producing them. They are made in the same way except they do not require firing -

The technical schools provide construction training for the various specialist skills -

With the expansion in tourism and the remittances from the “Guest Workers” to the Middle Eastern Countries, new buildings are being constructed throughout the island providing employment opportunities for both traditional and “modern” builders.

“Modern” builders will still follow the traditional customs when starting , completing and for the “opening of new buildings especially those houses and enterprises being constructed for Sri Lankan families.

(See also Sections under “Beliefs” on” Foundations” and “Opening”. Also see “ Occupations” sub sections on “Coconuts” where there is a description of acquiring and preparing the coconut wood roof timbers and links to relevant You Tube videos.)

The husband and wife work together to make the bricks.

They dig out the clay, and mix it with water.Then mould it in wooden moulds where they are left to harden in the sun. Then the sun hardened bricks are loaded into the kiln to be fired.

Their kiln for firing the bricks. They use a combination of wood and rice straw (purchased from paddy farmers after harvest-

When taken from the kiln, the cooled bricks are then stacked ready for sale.

Typical bricks. The holes reduce the required amount of clay and also provide insulation from the heat.

A stack of fired bricks. Bricks are made in different sizes using various sized moulds made by local carpenters.

Traditional house made of clay bricks with coconut thatch roof. As people build new houses they often use their older houses for cooking

New house under construction. As they have resources (e.g. from remittances from relatives who are “Guest Workers” in the Middle East, sale of rice etc.) they continue with the construction e.g. adding windows, plastering walls and decoration.

Brick-making small businesses

Clay pit, formed bricks drying in the sun

Stacked fired bricks to left and kiln to the right

This group of women entrepreneurs make bricks next to their paddy field

For further details on traditional practices associated with construction, see section -

https://www.sheppard.me.uk/sri-

And sub sections within “Occupations”

https://www.sheppard.me.uk/sri-

https://www.sheppard.me.uk/sri-

You Tube Video Links:

“Dramatic Felling Coconut Trees for Roofing Beams”

https://www.youtube.com/watch?v=_QraF6CzXbE

“Adze shaping roof beams”

https://www.youtube.com/watch?v=xkjcGw9oHAc

“Easy Money -

https://youtu.be/8emuMT5dpEU

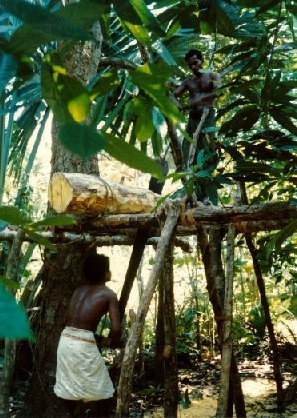

Traditional way of acquiring necessary timber. Now sawyers use chain saws. N.B. There is strict protection of trees and permission needs to be gained to cut down trees in the Jungle.

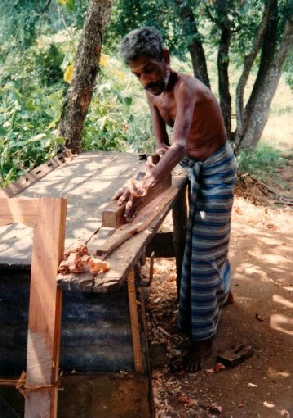

Village carpenters make windows and doors as well as furniture.

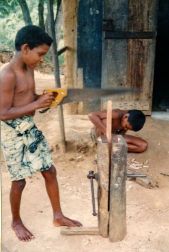

Carpenter’s young son learns the skills from his father.